The story of gold ceramics

Finnish family business since 1977

Kultakeramiikka Oy is a Finnish family business that was founded in 1977 in Nummi, now Lohja Municipality. The company was born out of a passion for making high-quality ceramics and a desire to bring them into everyday use for Finns.

The family business started on a small scale, and in the early years production was mainly done by hand turning and casting. Gradually, the company moved more and more to mass production, which is how the product models that are still in production today began. In 1989, production moved to Pihtipudaa and in 2006 to Estonia, near Rakvere.

Established Finnish brand

In our outlet stores, the product range has also expanded to other home products, such as kitchen and interior design accessories. We value quality and our own production in our company. We want to manufacture products using as many high-quality Finnish raw materials as possible and keep our production as close to us as possible.

Kultakeramikka is an established Finnish brand. Our dishes have been part of Finnish homes and kitchens for decades.

Design

The design and engineering work is carried out in Finland. All our products are carefully designed in collaboration with sales and our own factory.

Our products have been designed by, among others, Taru Tonder, Kirsi Ranta, Pinja Laine, Katja Saario, Paola Suhonen, writers Aino Havukainen and Sami Toivonen, and Saana and Olli. We also make many collaboration collections with other companies and business gift products.

Production process and responsibility

The tableware, designed and crafted in Finland, is mainly manufactured in our own factory in Pajusti, Estonia. Responsible production, high-quality raw materials and sustainable products are important values for us.

The Finnish raw materials in the products manufactured at our factory are quartz and feldspar. The domestic content of our raw materials is at least 35% of all raw materials. We manufacture the masses ourselves. Currently, we also manufacture some colored products with an audited contract manufacturer in Thailand. This is because our factory is not able to manufacture several colors due to capacity, and colors have been requested for our selection for years. You can see the country of manufacture of the product on the product card.

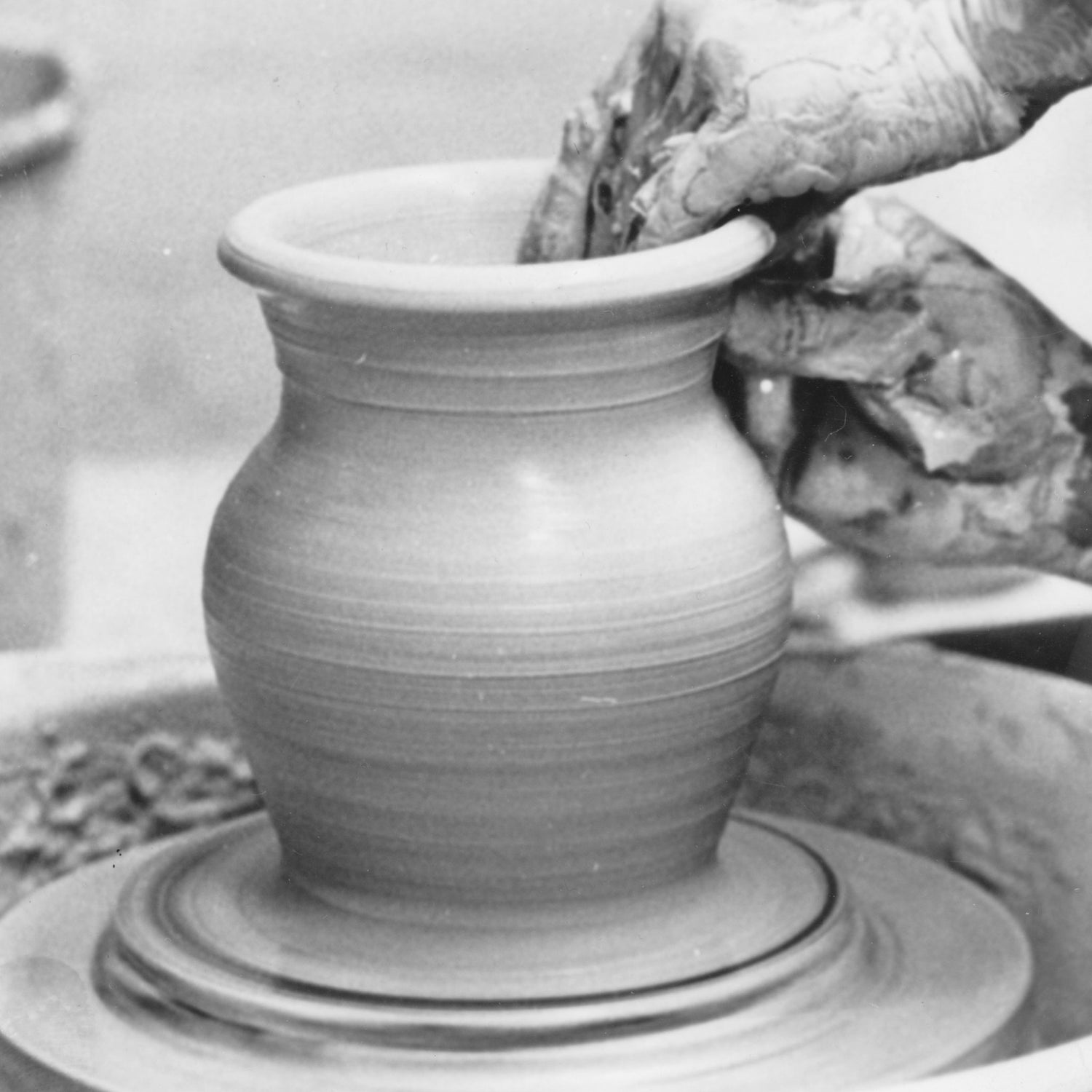

The journey of a ceramic vessel from clay material to finished product requires time and meticulous work. The vessel goes through many careful production stages before reaching the store shelf.

For our company, responsibility and transparency are the cornerstones of our operations. We strive to take economic, environmental and social responsibility into account in our direct and indirect operations.

In terms of environmental responsibility, we are committed to reducing waste and using renewable energy sources as much as possible. A large part of the electricity used by our factory comes from a solar power plant next to the factory. Waste heat from ovens, for example, is also recovered and used for heating the premises.

Since we manufacture a large part of our own production, we can directly influence the implementation of social responsibility, for example in terms of occupational safety and fair wages. Our partners are regularly audited by third parties in addition to our own supervision. Our operations are also guided by financial responsibility, meaning we take care of all financial obligations to our stakeholders.